Fundamentals of our system

|

Aluminium is not just found in household items. This element is the second-most abundant metallic element in Earth's crust after silicon. It's used in drink cans and other packaging, in aircraft and automobiles, and even in smart phones.

It is 8 percent of Earths crust by weight, making it easy to source. But it is lightweight, a third of the weight of steel and copper. Easy to mould fold and recycle. it is naturally resistant to corrosion and stands up to repeat use. |

|

Powder coating aluminium is a dry finishing process. It is the most widely used method of coating due to its high-quality, durable finish, allowing for maximized production, improved efficiencies, and environmental compliance.

Because of its high durability, it is the perfect system it use to coat our profiles. Available in hundreds of various colours, we even have the ability to dual coat, inside colour vary from the outside, on almost all our profiles. |

|

A solid aluminium section on its own doesn't bring much in terms of energy efficiency, so other materials that thermally bridge two sections, can create an system which can keep the heat in and cold out.

Using latest thermal algorithm software and design technics, Stayfix systems can achieve one of the lowest u values in the industry. |

|

Approximately 92% of waste material from the building industry in the UK is recycled. Recycled aluminium uses only 5% of the energy needed for primary production and 75% of current ingot production is from re-melt and recycled resources.

Compared to PVC or Timber, aluminium can be reused with minimal loss of material during the recycling process. |

|

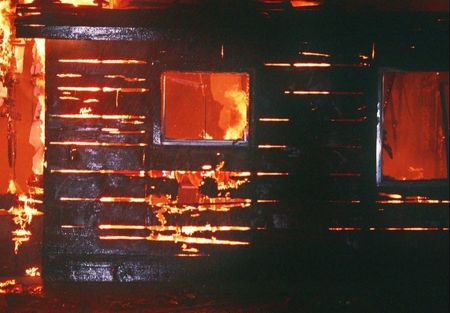

Due to its high melting point and non- flammable properties, aluminium is idea in window / door construction.

BS 476: Part 3 covers external fire exposure roof tests and the classifications laid down in the standard range from AA to DD. The first letter refers to the fire penetration performance and the second letter to the surface spread of flame. Aluminium and its alloys are rated AA, the highest possible under this classification system. More information. |

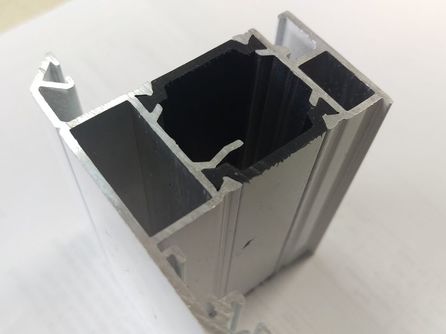

Extrusion process shown by Sistem extrusion plant.